Spoiled vaccines. Melted ice creams. Wasted pharmaceuticals. Moving temperature-sensitive goods responsibly is something companies can not compromise on.

For products that rely on precision conditions from factory to shelf – even a few degrees off can lead to product loss, compliance issues, and reputation damage. That’s where an IoT temperature monitor steps in, making sure the cold chain stays, well… cold.

In this blog, we will discuss how these smart devices work, where they’re used, and why they’re indispensable for modern logistics.

What Is an IoT Temperature Monitor?

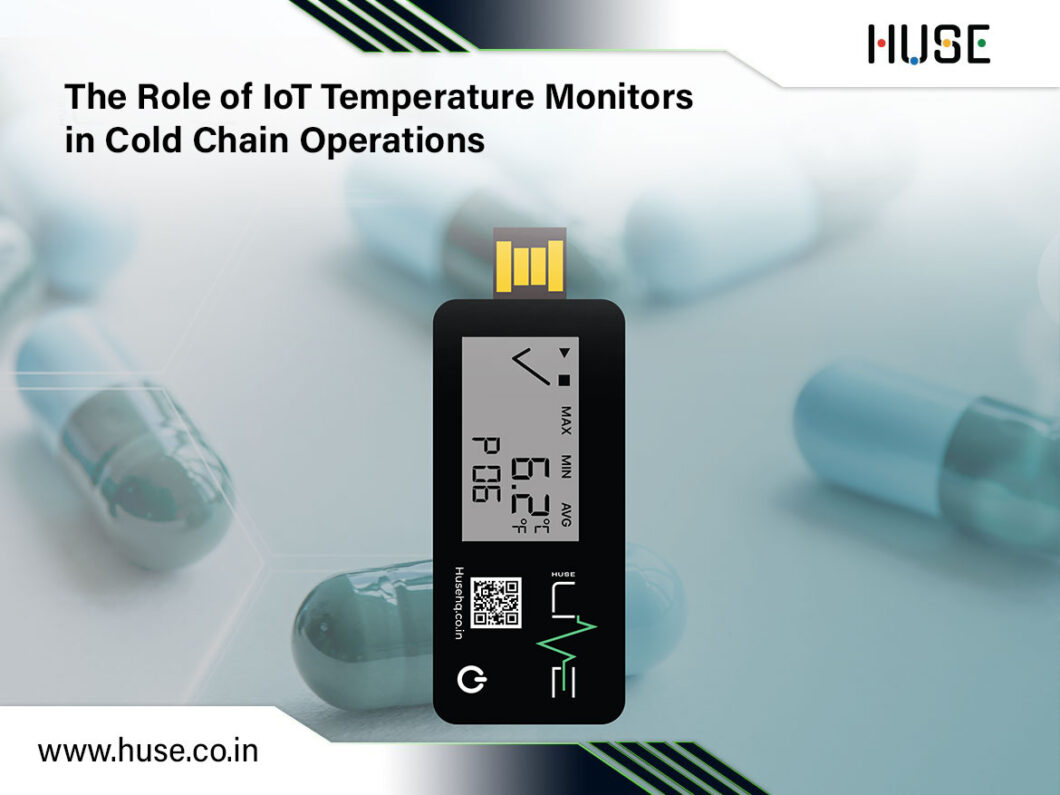

An IoT temperature monitor is a smart device that continuously tracks the temperature of a product or environment and transmits that data in real-time to a centralized platform.

Think of it as your digital watchdog, logging temperature, humidity, and other vital parameters using sensors, and alerting stakeholders if anything goes out of bounds.

Unlike traditional thermometers or manual logs, these devices use cloud-connected daq systems, temperature logging systems, and analytics to offer 24/7 visibility.

How Does an IoT Temperature Monitor Work?

In transit or at rest, these monitors send signals through Wi-Fi, Bluetooth, cellular, or LPWAN networks to let you know if that truckload of insulin is staying within its required range.

Some devices even offer predictive alerts using AI-based analytics, allowing you to fix problems before they happen. IoT temperature monitors consist of the following components:

- Temperature sensors (wired or wireless) that capture environmental readings

- A data acquisition system or daq system that collects, stores, and transmits the data

- A centralized temperature logging system, often cloud-based, that analyzes the data and raises real-time alerts when deviations occur

Applications of IoT Temperature Monitors Across Industries

Be it logistics firms or vaccine manufacturers, companies across the globe are actively deploying IoT temperature monitors in areas like:

- Pharmaceuticals: Monitoring vaccines, biologics, and critical medications during storage and global transit.

- Food & Beverage: Ensuring perishable goods like seafood, meat, dairy, and produce remain at safe temps.

- Life Sciences & Biotech: Keeping samples, reagents, and research materials stable in labs and clinics.

- Retail & Grocery Chains: Protecting product freshness across cold rooms, freezers, and display units.

- Chemical Manufacturing: Controlling ambient temperatures for hazardous or reactive substances.

Why Temperature Monitoring Matters More Than Ever

Cold chains are growing and getting more complex. With advancements across various sectors and the demand for goods spanning continents, maintaining temperatures has become more crucial than ever.

With stricter regulations, rising demand for biologics and frozen foods, and longer supply routes, the pressure is on to ensure zero deviation. A single breach in temperature can destroy thousands of units or trigger a product recall.

That’s why smart monitoring is a non-negotiable. A robust temperature logging system not only ensures real-time tracking but also records history, enabling traceability for audits, root-cause analysis, and compliance with regulatory bodies like the FDA, WHO, or FSSAI.

5 Reasons Cold Chain Monitoring Needs IoT Temperature Monitors

- End-to-End Visibility

Real-time monitoring using cold chain temperature data loggers ensures there are no blind spots, from processing plants to retail shelves. - Rapid Incident Response

Instant alerts allow teams to intervene when temperatures cross thresholds, reducing product loss dramatically. - Data-Driven Decisions

Centralized dashboards powered by daq systems help companies optimize routes, packaging, and storage practices. - Regulatory Compliance

Maintain airtight audit trails and ensure easy documentation for quality control and reporting standards. - Sustainability & Cost Savings

Reduced spoilage means less waste, lower energy consumption, and fewer recalls, directly impacting the bottom line.

What to Look for in an IoT Temperature Monitoring Partner

Not all monitoring solutions are created equal. As you scale, you’ll need:

- A platform that integrates easily with your temperature logging system

- Devices with multi-sensor support (for humidity, light, shock, etc.)

- Durable cold chain temperature data loggers suitable for international transit

- Support for mobile and tablet apps with multi-location control

- A partner who offers insights, not just raw data

Final Thoughts: It’s Time to Ditch Guesswork for Good

Whether you’re shipping seafood or storing vaccines, you simply can’t afford to operate in the dark.

An IoT temperature monitor tracks and protects, predicts, and prevents. And in a high-stakes cold chain environment, that makes all the difference.

So, if you’re still relying on manual logs or disconnected devices, now’s the time to upgrade. Smarter monitoring today leads to safer products and safer profits tomorrow.

At Huse, we offer a wide range of IoT temperature monitor systems designed to simplify your cold chain monitoring in a smarter, scalable way. Get in touch with our team today to find the right-fit solution for your operations.